This course has been superseded by the courses:

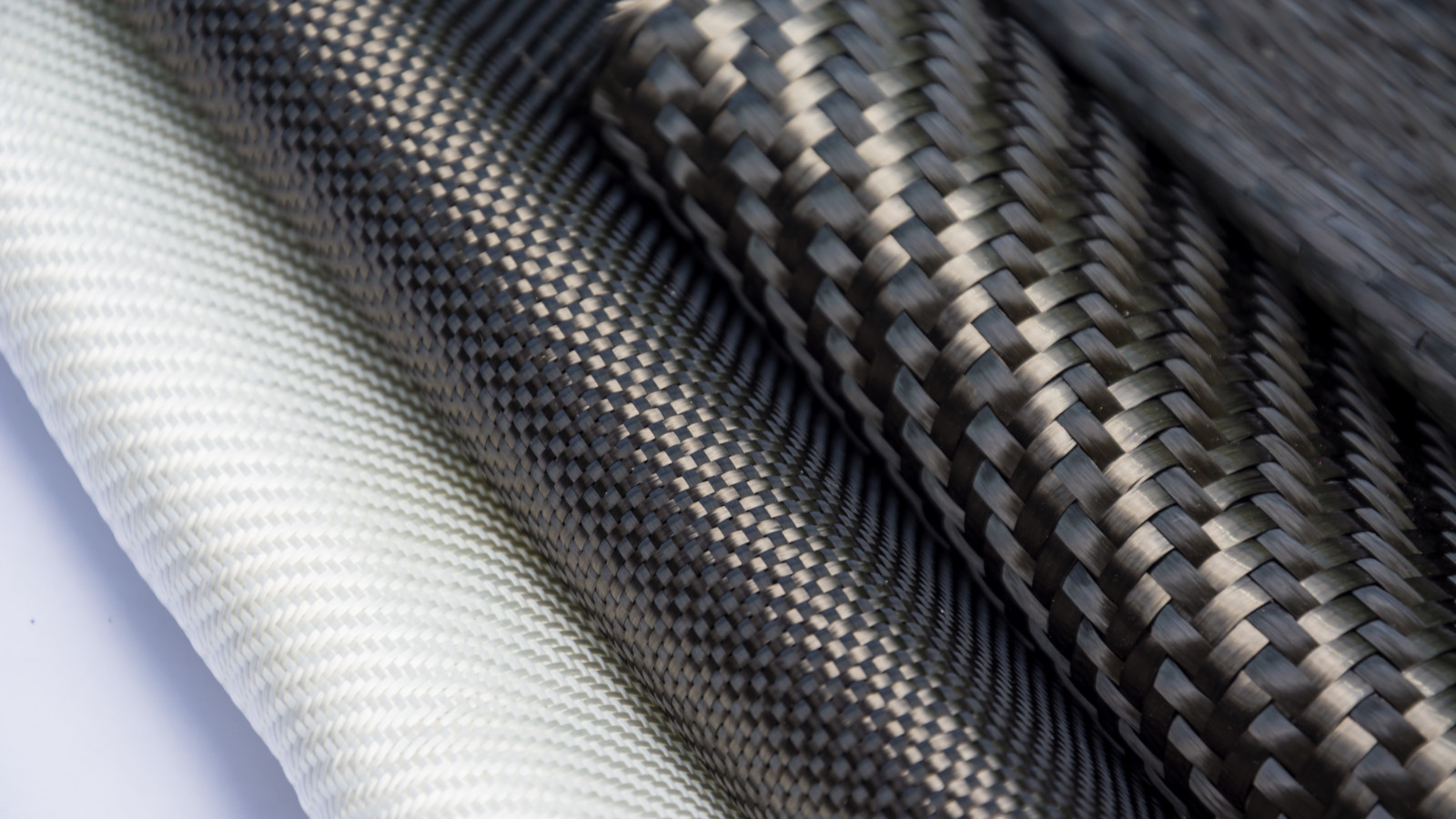

Composite Materials 1 & Composite Materials 2

As a replacement for this course, we’re excited to announce two new courses: Composite Materials 1 and Composite Materials 2. Composite Materials 1 is scheduled to launch in May 2016.

The new instructor is Lucía Díaz, who has led major glass-fibre repairs—including on naval vessels—and produced high-precision composite components for ferries and catamarans. In addition to being a Naval Architect and Marine Systems Engineer, she is Lloyd’s Register–certified in FRP vessel inspection and repair and holds a Master’s in Yacht Interior Design.

Welcome!

Welcome to Composite Materials 1.

If you want to learn about these materials, how to use them, and be part of this world, this course is for you!

What will you learn?

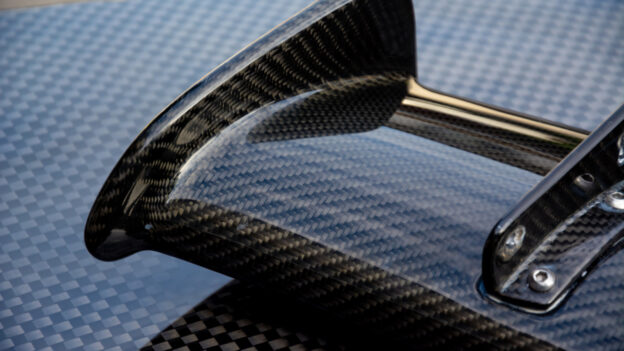

You will learn all the principles and theory that involve composite materials to understand what they are, their components, and what they can be used for in different applications, focusing mainly on the Naval Industry.

You will learn specific terminology, different processes, basic chemistry knowledge in the use of polymer matrix, how to properly read material datasheets, and criteria to select the correct or most convenient production processes, procedures, and materials for the particular project you may be working on.

Once this knowledge is settled, you will develop, together with the instructor, a basic laminate calculation spreadsheet for composite materials, which will be a very helpful tool to be used in your future projects.

After the course, you will be able to apply the knowledge acquired to use composite materials in manufacturing components and products.

Course organization

The course is video-based and on-demand and can be followed at your own pace.

It contains videos, quizzes, and downloadable documents and gives access to the course’s classroom, a virtual place to interact with the instructor and fellow students.

Students completing the course will obtain the Course Certificate.

– Resources:

- Video lessons.

- Written documentation (196 pages).

- Calculation templates (spreadsheets).

- Quizzes.

- Course Certificate.

– Classroom:

– Prerequisites:

- To follow the course, it is not necessary to have any prior knowledge of composite materials. However, a technical or engineering background will help you during the journey. Also, a basic background in physics and mathematical concepts is assumed.

- A minimum Navalapp membership level of “Subscriber” (free membership) is required to enroll in this course.

RINA Endorsement

After a thorough evaluation, the Royal Institution of Naval Architects (RINA) has found that Navalapp’s course Composite Materials 1 meets the Institution’s requirements for Continuing Professional Development (CPD). Therefore, RINA has considered that the course warrants recognition and has issued a Certificate of Endorsement.

During the evaluation, RINA studied different aspects of the course, such as learning aims, content and structure, whether the information is up-to-date and factually correct, students’ evaluations of the course, the supporting information and materials, the instructor’s expertise, the method by which the students are evaluated, and Navalapp’s organization standards.