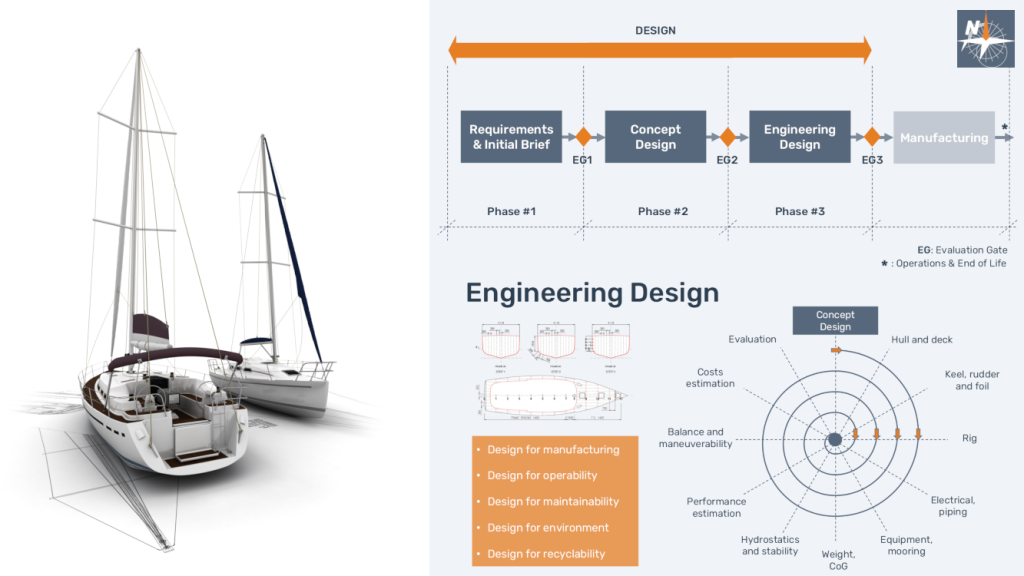

Yacht Design Office: the Design Process

In this article, we define a Design Process for yachts and other types of vessels based on our own experience, lessons learned gained in different projects, and industry standards. This Design Process combines at the same time both the Systems Engineering and the Spiral approaches.